Colored scleral contact lenses can work for people with dark eyes, but the effectiveness of the color may vary depending on the specific design and pigmentation of the lenses. Scleral lenses cover a larger portion of the eye, including the white part (sclera) and part of the cornea, providing a more significant color impact compared to regular contact lenses.

Here are some considerations regarding colored scleral contact lenses for people with dark eyes:

- Opacity and Pigmentation: The opacity and pigmentation of the colored scleral lenses play a crucial role. Some lenses are designed to completely mask the underlying eye color, while others may allow some of the natural eye color to show through.

- Vividness of Color: The vividness of the color may be affected by the natural darkness of the eyes. Colored scleral lenses may appear more vibrant on individuals with lighter eye colors, while the effect may be subtler on those with dark eyes.

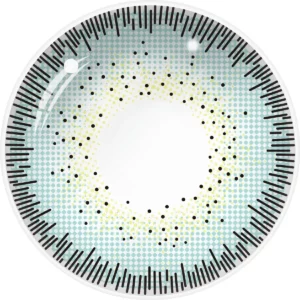

- Customization Options: Some manufacturers offer customization options for colored scleral lenses, allowing wearers to choose the desired color intensity and pattern. colored scleral contact lenses Discussing your preferences with your eye care professional can help you select lenses that meet your expectations.

- Try Before Purchase: If possible, try a pair of colored scleral lenses before making a purchase. Many contact lens practitioners offer trial lenses that allow you to experience how the lenses look and feel on your eyes.

- Professional Fitting: Colored scleral lenses, like regular contact lenses, require a professional fitting to ensure proper sizing, comfort, and optimal vision. Your eye care professional can help you find lenses that fit well and provide the desired aesthetic effect.

- Lens Brand and Design: Different brands and designs of colored scleral lenses may offer varying results. Some lenses are specifically formulated to provide vibrant colors even on dark eyes, while others may have a more subtle effect.

It’s important to note that colored contact lenses, including scleral lenses, are considered medical devices, and a prescription from an eye care professional is required for their purchase. Always follow your eye care professional’s recommendations for proper use, cleaning, and maintenance of colored scleral lenses to ensure eye health and safety.