Nonwoven machinery manufacturers are companies that design, manufacture, and supply machinery used in the production of nonwoven fabrics. Nonwoven fabrics are used in a wide variety of applications, including hygiene products, medical supplies, industrial materials, and more. In this essay, we will discuss the role of nonwoven machinery manufacturers in the nonwoven industry, their products, and their impact on the global economy.

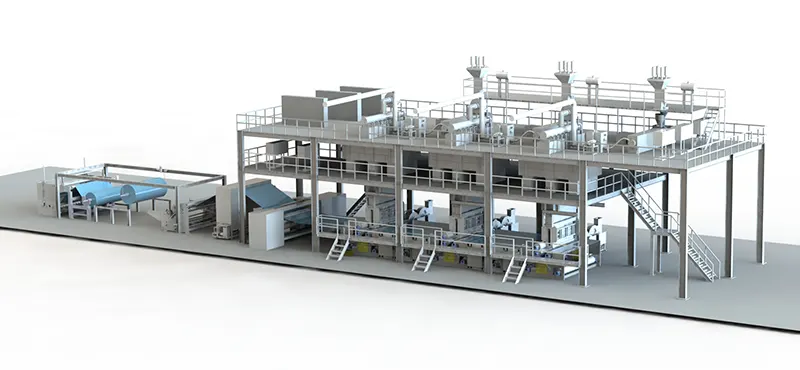

Nonwoven machinery manufacturers play a crucial role in the nonwoven industry. They are responsible for designing and producing the machinery that is used to create nonwoven fabrics. This machinery includes carding machines, nonwoven machinery manufacturers needle punching machines, spunbond machines, meltblown machines, and others. The quality and efficiency of this machinery directly impact the quality and cost of the final product. Therefore, nonwoven machinery manufacturers are responsible for driving innovation and development in the industry.

There are many nonwoven machinery manufacturers around the world, including companies in the United States, Europe, and Asia. Some of the most well-known manufacturers include Reifenhäuser Group, Oerlikon Nonwoven, Rieter, and Andritz. These companies have a long history in the industry and are known for producing high-quality machinery that is reliable and efficient.

One of the key products of nonwoven machinery manufacturers is the carding machine. This machine is used to blend and align fibers to create a web that can be further processed into a nonwoven fabric. The quality and efficiency of a carding machine directly impact the quality and cost of the final product. Carding machines can be designed for a wide variety of applications, including hygiene products, medical supplies, and industrial materials.

Another important product of nonwoven machinery manufacturers is the needle punching machine. This machine is used to interlock fibers to create a fabric that is strong and durable. Needle punching machines can be used for a wide variety of applications, including automotive and construction materials, geotextiles, and filtration products.

Spunbond machines and meltblown machines are also important products of nonwoven machinery manufacturers. These machines are used to create nonwoven fabrics from thermoplastic polymers. Spunbond machines produce a web of continuous filaments that are thermally bonded, while meltblown machines produce a web of microfibers that are also thermally bonded. These fabrics are commonly used in hygiene products, medical supplies, and industrial materials.

Nonwoven machinery manufacturers have a significant impact on the global economy. The nonwoven industry is a growing industry, with a wide range of applications and uses. The demand for nonwoven products is increasing as they offer many advantages over traditional fabrics, including lower cost, greater durability, and improved performance. This growth in demand has driven the development of new machinery and technology by nonwoven machinery manufacturers.

In addition, nonwoven machinery manufacturers create jobs and contribute to the economy in many countries around the world. They also support the growth and development of related industries, including the raw material suppliers and the manufacturers of finished nonwoven products. The nonwoven industry is a major contributor to the global economy, and nonwoven machinery manufacturers are an important part of this industry.

In conclusion, nonwoven machinery manufacturers play a critical role in the nonwoven industry. They are responsible for designing and producing the machinery used to create nonwoven fabrics. The quality and efficiency of this machinery directly impact the quality and cost of the final product. Nonwoven machinery manufacturers have a significant impact on the global economy, creating jobs and supporting the growth and development of related industries. With the increasing demand for nonwoven products, nonwoven machinery manufacturers will continue to play an important role in driving innovation and development in the industry.